Robert L. Lynch

Before we get too far ahead of ourselves building stuff, I’d like to offer some tips on the materials we’ll be using. I work a lot with used pallet wood, primarily because I’m cheap and I can generally get it for free. If you’re going to be using pallet wood, there’s three important points you need to know before you get started: (1) Where to get used pallets, (2) which types of pallets are safe to use for your project, and (3) how to break down pallets once you’ve got them.

Where to get pallets

Many businesses receive shipments on pallets, but if you’re looking for good sources you should start thinking small; small businesses specifically. Big box stores certainly get their fair share of pallets, but generally the big guys already have processes in place for removal and recycling of shipping materials. Your best bet is to check with small local businesses. Many of these smaller shops don’t have the resources to regularly dispose of pallets, so they just pile up until they can find someone to get rid of them. Plenty of places will be happy to give you as much free material as you want because it’s less of a disposal cost for them. If you’re the networking type, you can ask around and probably find someone in your circle who works at a business that receives shipments on pallets. Chances are, they’d be happy to find someone to take them off their hands.

When looking for businesses that might have pallets available, a good tip is to check in with soon-to-open or newly-opened businesses that are still stocking their inventory; there’s a good chance most of their new supplies were shipped in crates or on pallets that they need to get rid of.

Remember though, if you’re getting pallets from a business, be sure to ask someone from the business before taking anything. Just because you see a pile of pallets leaning against a wall outside, that doesn’t automatically make them free to take. A lot of shops that get deliveries on pallets pay a deposit on them, and get charged if they’re not returned. Basically, unless there’s a sign on them that says “free”, it’s best to get the OK before loading up.

Another great source for finding pallets and other reclaimed wood is online classifieds, like Craigslist or Facebook community pages. Often you’ll be able to find multiple listings for free pallets from people and businesses that would rather give them to you than pay to have them hauled off.

What pallets are safe?

As far as safety goes, the first thing to consider is basic common sense. If a pallet has spills on it, like oil, chemicals, or food, you should probably pass on it. Same goes for pallets that have been sitting outside in the elements for a long time. These can contain molds, bacteria, fungus, or any number of other nasty stuff you don’t want to get in to.

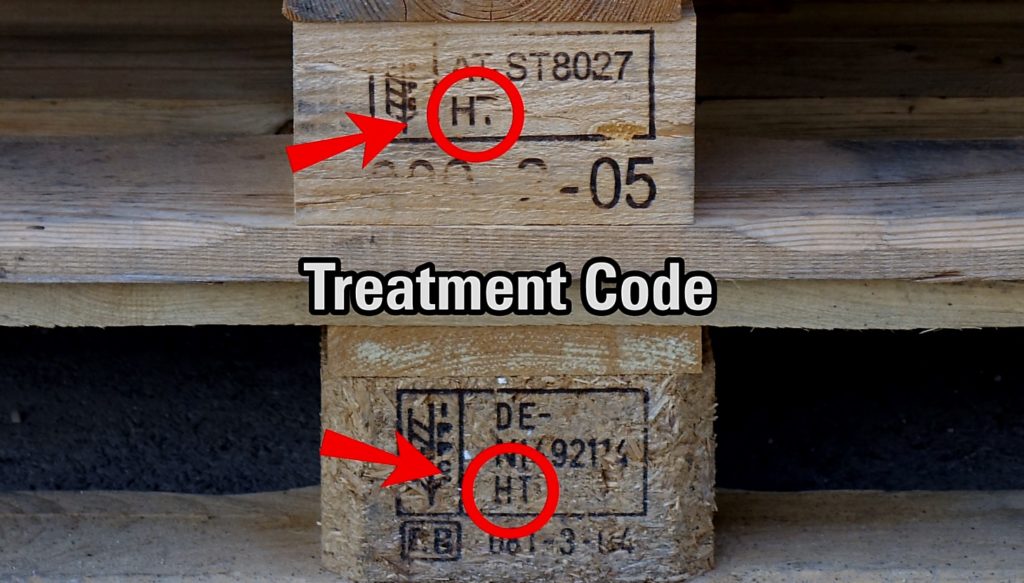

Secondly, you can look for an IPPC pallet stamp. All internationally shipped pallets are marked with stamps that indicate country of origin and treatment code. The treatment code is the key info to look for here. International pallets are treated in a variety of ways to prevent invasive insects or plant diseases from spreading; the treatment code on the IPPC stamp designates which method was used. By themselves pallets marked HT (heat treated), KD (kiln dried), and DB (de-barked) are safe to use, but what you need to watch out for is if it is marked MB, meaning methyl bromide. Methyl bromide fumigation is a very effective pesticide that kills invasive species like pine beetles, but it’s linked to a lot of human health problems and ozone depletion. This treatment method is now banned in many countries, but it’s still commonly used in some regions including Asia. If you pick up an MB pallet, DO NOT use it for projects or firewood; instead contact a disposal company to get rid of it for you.

If you’re in Europe, you might run into pallets marked EUR or EPAL. These refer to the European Pallet Association, a licensing organization that sets standards for load carrying. The current standards, applying to pallets, EPAL, ban the use of chemicals, and are effectively identical to a pallet marked HT-DB. Those are safe to use for projects or burning. Pallets marked EUR are more rare to find because they refer to an older version of the European standards. Those were more lax regarding chemicals, so they may or may not be safe to use. These should be avoided unless also approved by EPAL.

Unstamped pallets are called “national pallets” because they aren’t used for international shipping. As they are not used internationally, the need to prevent the spread of insects is not really an issue, so most domestic pallets aren’t treated. These can generally be considered safe for secondary use.

Colored pallets don’t inherently represent a risk to use, but use your best judgment if you think they might be unsafe. The coloration doesn’t refer to any specific treatment or chemical use, but instead denotes that the pallet is provided by a pallet rental company that maintains and repairs the pallets for customers. Red pallets come from either LPR in Europe or PECO in the US. Blue pallets come from CHEP in Australia, and brown pallets come from IPP in Europe. Out of these, the PECO pallets are the safest to use, because they aren’t chemically treated and are regularly tested by third-party inspectors.

If you can’t establish whether a pallet is safe, don’t use it for any projects that will be inside a home or would come into contact with food. Regardless of the pallet itself, be sure to always follow safe procedures when working with it. Always use a mask or respirator when cutting or sanding to avoid breathing in particles or pollutants.

How to break down a pallet

There are a lot of tutorials online that show quite a few different ways of breaking down a pallet, so if you’re not thrilled by what I show you, I’d suggest searching those tutorials out and finding a method that works for you. That said, here’s the three ways that have worked the best for me:

1) The classic hammer and pry bar method

This is also known as the brute force method. It’s pretty basic and only requires basic hand tools. You start by loosening the planks by hammering them from the underside, until you get enough of a gap to fit a pry bar between the deck board and the stringers. Then, use your pry bar to lift the boards the rest of the way. This is pretty effective, but it’s very labor and time intensive, and you have a chance of losing material on the edges if the wood splits.

However, if you want something quicker and that minor lost material isn’t an issue try…

2) The circular saw method

This is one of the quicker ways, but it’s also a bit messier. Set your circular saw’s depth to just a hair above the thickness of the pallet’s deck boards. After that, cut all the way through the length of the pallet on both sides, inside the nails on the outer stringers. Once the boards are free on both sides, you can usually wiggle them free from the center without any tools.

Of course if you want speed and conservation of materials, there’s one even better way to go…

3) Using a pallet Breaker

If you don’t mind dropping $50 on a specialty tool (or if you feel confident welding your own), I highly recommend using a pallet breaker. You can pick these up online or from industrial supply stores or online stores like Amazon, and if you have a lot of pallets to tear down, it’s a major time saver. With this, all you need to do is slip it under the planks and push down. The breaker acts as a lever, and pushes against both the boards and the stringer. In my experience, this is the most efficient way to salvage wood, both because of how fast you can break up pallets, and because it creates the least waste material by means of broken edges.

I’ve seen and tried some methods that involve cutting through nails with either a hack saw or reciprocating saw, but I feel like there’s too much room for error there, plus it makes it pretty hard to pull the nails out when you’re done.

Regardless of what method you use, once you have the boards off, you can use a claw hammer to pull off the remaining nails, and then clean the wood before you do anything with it. Soap and hot water is fine if you’re just wiping down warehouse dust, but if you have a power sprayer, this is the time to get it out. Once you clean the wood, set it out in the sun, or keep it somewhere warm and dry to get rid of the additional moisture in the wood.

Conclusion

Hopefully, that provides you with a good starting point for working with pallets as reclaimed wood. Just remember, watch out for mold and chemicals, wear safety gear when you work, lift with your legs, etc… Follow common sense safety rules and you’ll be building in no time.